Behind the scenes

Why this page?

We started this page because most of the other the info/pictures on the website are of the clean type “end result” product ones. What interest us is the craft and process behind a good result and the development needed to keep improving. So we feel like sharing this with you.

Please be aware that only a fraction of what is going on is visible on here. It is so busy that we don’t have time to maintain this page properly. More frequent / general updates can be found on the Facebook page.

We like to give people the opportunity to have a realistic look at what we am working on behind the scenes, how it is to run a workshop like ours and what kind of challenges we encounter. Basically the things that happen besides instrument making. And usually after or before normal work times. Often when normal people sleep.

You’ll likely see things that you wouldn’t expect. Machine maintanance, tool making, furniture upgrades, travel, etc.

Enjoy!

Something NEW

Over the years we have made several top action rotary instruments, but none was a cool (and good) as the instrument We are working on at this moment in time. No more “is this a ganschhorn?” questions….

Manufacturing forming tools!

Made a roller tool and an inner mandrel for producing new parts for our top action flugelhorn which we call the Twugelhorn. Sometimes it takes a few days of tool making to be able to produce -exactly- what we want instead of using “generic” parts available from commercial suppliers. This is how we produce unique instruments. This was a lot of work but worth the effort!

The first mouthpiece tops!

We have managed to program our cnc lathe to cut a mouthpiece rim, cup and throat. Very precisely…

Next up is setting up for the threaded parts of the mouthpieces since we have the wish to offer them “warburton” style with seprate tops and backbores.

Been very busy! An update.

There isn’t always time to maintain this part of the website. But stuff had surely been happening. Besides the regular work on instruments we have been very busy working on the cnc lathe and the process of “scanning” existing mouthpieces to reproduce on the CNC machine. The CNC adventure is very time and money consuming and has a steep learning curve. In the pic you can see how the tool offset process is organized.

Digital Readout Fitted!

The recently acquired milling machine has been in use for a few weeks. This week we have added a digital readout system to it. This is another one of these jobs done after normal worktimes.

Drilling and tapping into a nice machine like this to fit the modern parts is a bit stressful. But it is done! This makes working with it a lot easier and faster. We hope that maybe in the xmas holidays it is possible to give the machine a fresh coat of industrial lacquer.

New lathe tools

We upgraded our main lathe with new -swiss made- toolholding. These are the actual toolholders. They clamp onto the so called Mother-block that we already cleaned and is already mounted onto the lathe. We used to have a collection of asian tools for this that were pretty well made but not repetitively accurate enough to program their positions in the Digital Readout system. This set is of better quality and comes all from the same factory and should solve the “problem”. We got them used and spent a few ours to clean and grease it all up. Nothing as satisfying as blackened steel that has a film layer of machine oil on it.

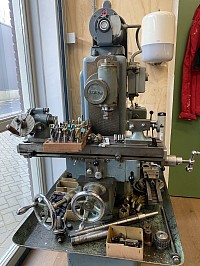

Welcome Tom Senior Mill!

The “new” mill has been installed! Now comes the process of sorting all the accessories out, and prepping the machine for a new coating of industrial grey paint. A great new machine for making tooling and parts. we love these old, sturdy machines…

Machine pickup day!

More CNC setup! Our new tool table and boring block holder are in!

If you scroll down a little you’ll see the drawing of this tool holding table. It was produced by a local business and We are very happy with it. It is a huge upgrade to the machine. The block mounted on top needs some holes bored into it to hold boring tools for rims and cups. On the “ears” of the table another type of tool wil be mounted to turn outside diameters/shapes.

Improving workflow

We are still in the setup process for the CNC lathe. We picked up a big 48” HD monitor to improve workflow. No more squinting at a small screen :)