Mouthpiece Services

MG designed and produced mouthpieces

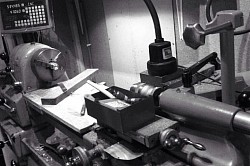

Up to now our new mouthpieces were produced completely by hand on a manual lathe, resulting in unique pieces. We still do this when we modify a mouthpiece on request but our goal is to offer a base range of pieces produced, engraved/stamped and plated in house to very tight tolerances.

To offer this consistency over the whole range of mouthpiece products we have invested in dedicated CNC machines, 3D measuring and drawing and professional plating equipment which eventually will also allow us to do offer proper mouthpiece copies besides offering our range of own mouthpieces.

If you have any wishes/enquiries about our mouthpiece line and/or services then please contact us.

Two piece baroque trumpet mouthpieces

We have already been working on new CNC produced mouthpieces for baroque trumpet. These are available in screwtops and backbores to give you more control and save you money in the long run. The smaller size cups (comparable with around a 3c size) and standard backbores are already available. The bigger mouthpieces and tighter and larger backbores are still in development.

In the near future we will change this page on our website and allow you to choose and order all our baroque mouthpiece parts directly from here. But since we don’t like to force or rush things or offer products prematurely this can take some time.

If in the meanwhile you have wishes concerning baroque trumpet mouthpieces then please contact us for more up to date information.

Custom mouthpiece Work

Sometimes our mouthpieces are (partial) duplicates of mouthpieces that are no longer commercially available or “special request” pieces. These we generally produce in screw tops and backbores using “warburton” or “breslmair” tread. In the past we used to do this all with our self built manual duplicator machine but since that had its limits and we have invested in CNC equipment we are also doing this work digitally. We are working out some very nice ideas at the moment that will allow you to take control over the custom work we do for you. This includes some very sophisticated realtime online processes that we will present as soon as it is ready. If in the meanwhile you’d like to have work done on your mouthpieces then please contact us with your enquiries.